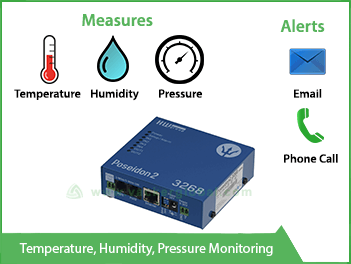

Individual evaluation of the 3 basic physical parameters namely pressure, temperature and humidity in a simultaneous, synchronous and automated manner has a plethora of industrial applications. A combined system for pressure, temperature and humidity monitoring, recording, alert, transfer over internet etc. can be a perfect device for the above-mentioned task.

What are the parameters that make for an efficient pressure, temperature and humidity monitoring systems?

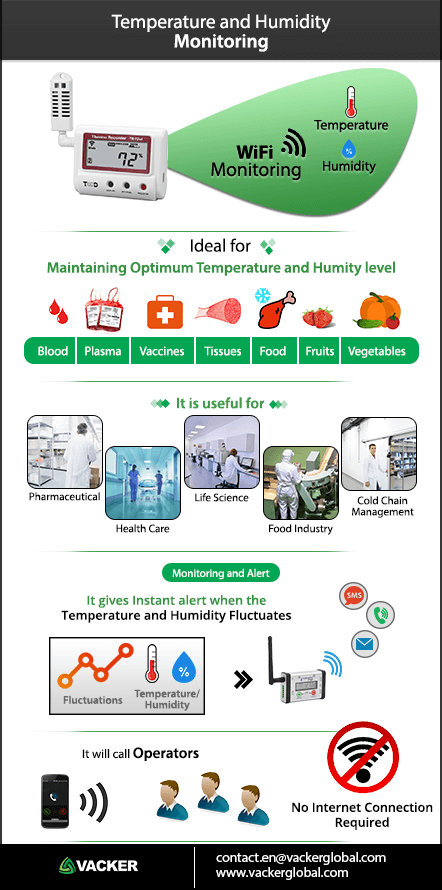

A monitoring system is basically an electronic device that collects information about various physical entities in an automated manner. In regards to the pressure, temperature and humidity monitoring systems being talked about, all entities in consideration are recorded in a simultaneous manner thereby providing faster information processing capabilities and even greater connectivity by sharing of information via the internet itself.

By banking on the concept of digital fusion, these monitoring systems focus on balancing the scales of their functionality subject to three main parameters. Those parameters are that of low power consumption, compactness of size and high PTH accuracy. High PTH accuracy is important because the above-mentioned physical entities are highly susceptible to changes in the environment. A simple example could be given by stating that altitude affects pressure measurements in a significant manner. If the pressure measurements are highly accurate, the monitoring system can double up as an Altimeter as well.

A compact size facilitates usage of such monitoring systems in multiple sectors. Some of the fields were adjusting the parameter of size can create wonders are that of weather forecasting, personal health monitoring, home automation, and navigation. Low power consumption is another important prerequisite for pressure, temperature and humidity monitoring systems to find wider application in the industry as it facilitates the use of such sensors in mobile devices as well. An amalgamation of this kind is incremental to increasing the functionality of monitoring systems.

Applications of Pressure Sensing

An entity that is defined in terms as simple as force per unit area exerts an unmatchable significance in various industrial applications. Pressure sensing applications derive their roots in the crux of almost every industry around the world. From healthcare to packaging and even manufacturing, pressure sensing applications are significant. The following uses of pressure sensing are the most imperative with regard to industrial procedures:

- Altitude Sensing: High PTH accuracy that is quite obviously inclusive of high-pressure sensing accuracy makes it possible to measure the altitude. The logic behind this operation is the pressure changes with increasing or decreasing altitude. By making use of the recordings in the appropriate mathematical formulae, pressure reading can directly co-relate to altitude. Altimeters come calibrated with prerequisite required for making the pressure based calculation on altitude.

- Flow Sensing: Flow sensing is an application of the measurement of differential pressure. By being in concurrence with the Venturi effect, pressure monitoring systems record various readings for the differential pressure. These differential pressure readings further facilitate measurement of the rate of flow through a constricted section of a pipe.

- Depth Sensing: The level of water varies directly with the pressure coursing through the liquid. A simple equation calibrated into pressure monitoring system concerning pressure, the density of the liquid and standard gravity can be easily used to establish a correlation with the height of fluid column above pressure sensing apparatus.

Applications of Humidity Sensing

A humidity sensor or a hygrometer is a device used to measure the amount of moisture present in the air. Furthermore, by comparing the moisture in the air at a particular instant to that of the moisture at a specific temperate of air gives the reading of relative humidity.

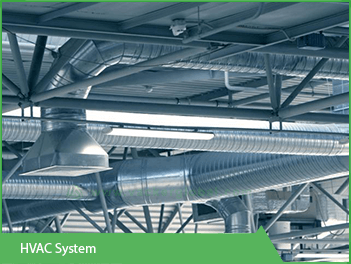

- HVAC Systems: Beyond any doubt, humidity sensing finds its greatest application in home heating, ventilation and air conditioning systems. HVAC systems find usage in various environments like offices, greenhouses, industrial establishments, and even automobiles.

- Humidity Monitoring in Massive Industrial Settings: In large industrial spaces, humidity sensing devices like the HCT01 operate at a sensitivity reading of 0.25 pF / %RH. The humidity range captured by such humidity sensor is that of 0 to 100% RH, where RH stands for relative humidity. Even though HCT01 isn’t a system with pressure, temperature and humidity monitoring capabilities, it gives us a fair idea what the monitoring systems with such extended capabilities can do.

Types of Temperature Sensing Devices

Like any other sensor, a temperature sensor is a device that can measure the entity in consideration i.e. temperature in real-time and give it a quantifiable representation. Temperature sensor come in various types, and subject to such classifications, they facilitate several industrial applications. The various types are detailed further:

Thermistors

A thermistor is a device that makes real-time variations in its physical resistance as changes in temperature come into existence. The raw materials generally used to make thermistors or temperature sensitive resistors are manganese, nickel oxides coated in glass or cobalt.

Based on the properties of the semiconductor materials that make up thermistors, they exhibit a negative temperature coefficient. That means that with an increase in temperature, the resistance of thermistors goes on a downward spiral. However, adjustments in the raw materials can facilitate construction of thermistors with positive temperature coefficients as well.

The following equation calibrated into temperature sensing devices composed of thermistors is used to make the appropriate measurements: - A, B, C are constants, R denotes the resistance that is measured in the SI unit of Ohms, and T is the temperature measurement in the SI unit of Kelvin.

Resistive Temperature Detectors

RTDs are devices made up of metal coils that a resistance subjective to temperature changes. RTDs improve on the biggest shortcoming of thermistors i.e. the inability to produce absolutely accurate temperature readings. With positive temperature coefficients and low sensitivity, the most common RTDs generally have a resistance value that measures to be 100 ohms at 0 degree Celsius.

RTDs can handle temperatures as low as -200 degree Celsius and as high as 650 degrees Celsius.

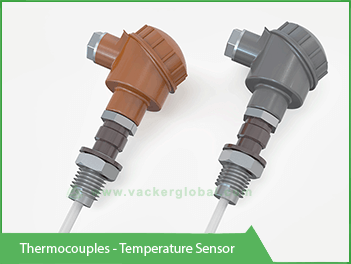

Thermocouples

Thermocouples are the most common devices used for temperature sensing. Due to their wide temperature ranges and ruggedness, they find applications in industrial spaces as well.

The response to temperature change in the case of thermocouples is instantaneous and thus, snappy and accurate measurements are facilitated.

The general range for temperature measurements in thermocouples is that of -200 degree Celsius to 2000 degree Celsius.

Applications of Temperature Sensing

If we talk about the applications of Temperature sensing, it’s obvious that there is an array of temperature sensing applications out there that can be benefitted from a proficient Pressure, temperature & humidity Monitoring system. From measuring the temperature in a negative spectrum of the temperature range to over thousands of degrees, temperature sensors amidst PTH Monitoring systems are creating new benchmarks. Let’s talk about the key temperature sensing applications that can be aided with a PTH Monitoring system in an exuberant way.

- HVAC Systems: HVAC systems are generally equipped with humidity measuring sensors along with temperature measuring sensors as well.

- Pharmaceutical Applications

- Heat Sensing in the Food and Beverage sector

- Heat Flux sensors

- Applications in the Oil Industry

The Concept of Digital Fusion

The market is filled with separate sensors that measure temperature, pressure and humidity respectively. However, the train of innovation is being led in the direction of sensors that simultaneously measure all the three entities being talked about. The general ranges in which the individual components of such monitoring systems function are detailed as follows. The pressure generally measures between 10 to 2k Mbar.

The temperature range lies between -40 degree Celsius and 200 degrees Celsius. Relative humidity measures lie in the range of 0 to 100% RH. A fully calibrated sensor that banks highly on the parameter of low power consumption operates in a range of 1.5 volts to 3.6 volts. The all-in-one or Digital Fusion blend that has been offered to customers in the form of a PTH Monitoring system is breaking the stereotypes with its exquisite all-in-one value calculations. One can literally leverage the speed & accuracy of a deemed PTH Monitoring system for the purpose of obtaining important analytical data.

Applications of Temperature, Pressure, and Humidity Monitoring Systems

The individual applications of the sensors that separately measure the 3 above-mentioned physical entities have already been covered. However, when a device that operates on the concept of digital fusion comes into a function, the industrial applications are further amplified. The detailed application analysis can be better presented by bringing the detailed account of the PUC 24 to light.

The PUC 24

The measurement ranges in this device are freely scalable in the range of ±100 Pa or ±250 Pa. The error associated with the PUC 24 is that of ± 0.5 % of max. value. With the overload capacity of 200x, this device is well equipped to handle unprecedented measurements as well. The PROFIBUS DP interface makes integration with central building control systems a task that doesn’t require enormous amounts of brainstorming and efforts.

This pressure monitoring system comes with two electrical inputs for the measurement of temperature and humidity as well. When used in air-conditioning systems or other sectors, all physical entities are displayed on the LCD that comes onboard. The PUC 24 can be easily mounted on the walls of laboratories, clean rooms, operating theatres and pharmaceutical plants. The fact that it operates with air and all other non-aggressive gases makes it perfect for the above-mentioned settings. The 25 ms record time of the sensor makes real-time observations quick and timely.

The IP65 casing lends it the necessary ruggedness. An alarm system provides for a failsafe against unusually critical values as well. The measurement of differential pressure, positive overpressure and negative overpressure further extend the number of uses of this wall mounted temperature, press and humidity monitoring system. The user software that accompanies the PUC 24 further increases the functionality of the monitoring systems installed in the device. Connections can be established via USB or the RS 232 interface.

All in all, the PUC 24 is a combined system for pressure, temperature and humidity monitoring, recording, alert, transfer over internet etc. that mainly finds applications in clean rooms.

PTH Monitoring system: suitable for your endeavours

It’d be wise to say if you’re looking forward to calculating the absolute values of physical parameters like Pressure, temperature, humidity etc., then a proficient Pressure, temperature & humidity monitoring system can be of great worth. The compactness and high level of accuracy that comes handy with PTH Monitoring systems make them unique as well as most sorted ones. As a user, you can deploy a good PTH sensor in places like Hospitals, storage facilities, energy conservation prospects, offices and even your homes.

Keeping the potential physical parameters in control is what is required here. One can keep their products safe and secure while they are piled up in storage facilities, measurement of pressure, temperature and humidity were never so easy. With a great compactness, comes a great calculating spectrum for temperature detection. PTH monitoring systems can measure temperature values as low as -50 degrees Celsius to 1300 degrees Celsius with much ease. Therefore, industries can leverage this ability of the monitoring systems & can move towards novelty in their operations.

Reliable parameter measurement & HVAC support:

The worth of pressure based applications is inevitable, altitude sensing, as well as flow sensing aspects of pressure measurements, are something that must be stressed upon. Whether you are required to measure the pressure which varies with altitude or you wish to record multiple readings for differential pressure, PTH Monitoring systems are always available at your disposal. The measurement of rate flow through the pipe has become so easy as well as accurate.

You can go for a proficient Pressure, temperature & humidity monitoring system, you might stress upon the power it consumes as well as the remote connectivity aspects, such as recording, alert, transfers over the internet etc. When HVAC system gets blended with a PTH Monitoring system, the results can be your pick for an out of the box parameter calculation. Best suited for homes, offices and commercial use, pick your PTH Monitoring system.