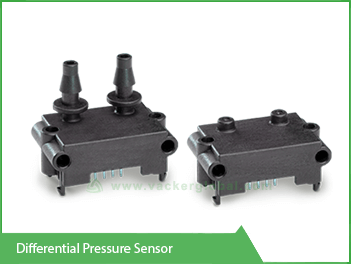

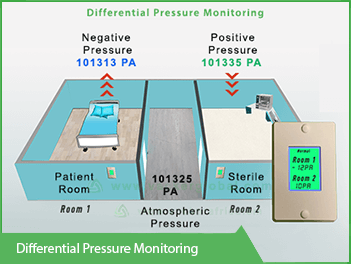

Differential room pressure sensors, negative room pressure sensors and positive room pressure sensors are all one device with these three functionalities. There are many commercial applications, which require a pressure difference between the two rooms. We need to use differential pressure sensors to monitor the pressure difference for such applications. Examples are hospital rooms, pharmaceutical plants, clean rooms, isolation wards, laboratories, electronic manufacturing plants etc. Depending on the application, a room has to maintain a higher or lower pressure compared to the outside area. Technically, we call it as differential pressure. The room with higher pressure is having positive pressure. Similarly, the room with lower pressure is at negative pressure.

We are supplying numerous types of differential pressure sensors for such applications.

Negative pressure & differential pressure sensor for monitoring isolation rooms, Clean Rooms, CSSD & operation theatre

Our differential pressure monitoring system is useful for positive pressure rooms, and negative pressure rooms. These are available in 2 models viz. VAC-CPS-6020 and VAC-CPS-6040. VAC-CPS-6020 can monitor up to 2 rooms while VAC-CPS-6040 is for up to 4 rooms. It is ideal for applications where quick access to essential parameters is needed such as clinics, hospitals, clean rooms, pharmaceutical plants, laboratories, and sterile rooms.

Our differential pressure monitoring system is useful for positive pressure rooms, and negative pressure rooms. These are available in 2 models viz. VAC-CPS-6020 and VAC-CPS-6040. VAC-CPS-6020 can monitor up to 2 rooms while VAC-CPS-6040 is for up to 4 rooms. It is ideal for applications where quick access to essential parameters is needed such as clinics, hospitals, clean rooms, pharmaceutical plants, laboratories, and sterile rooms.

Features of Pressure monitoring System, model no. VAC-CPS-6020/40 for isolation rooms, clean rooms

- This differential pressure monitor has a continuous operation that tracks the operations 24/7.

- VAC-CPS-6020 can m

onitor up to 2 rooms while VAC-CPS-6040 can monitor up to 4 rooms.

onitor up to 2 rooms while VAC-CPS-6040 can monitor up to 4 rooms. - It features slave panels to monitor the surrounding rooms.

- You can attach up to 10 panels to the main panel.

- Smart sensors and digital Modbus interface are used in the device

- This dynamic monitor system has high accuracy.

- Compared to conventional analogue systems, this negative pressure sensor monitor has a small maintenance cost and fast start-up.

- It is a device that is quick and easy to install.

- Both models of negative pressure sensors work in single room mode with either negative or positive pressure.

- It's easy to use for the workers, green implies that pressure value is fine while red means that it exceeds the entered pressure value.

Specifications of Room pressure Monitor System, model no. VAC-CPS6020/40

- This room pressure monitoring system is ideal for applications such as operating rooms, pharmacies, and laboratories.

- This pressure sensor system, model no. VAC-CPS6020/40 is a flush-mounting device. If flush-mounting is not possible; this can be installed on the wall using a bracket/box.

- The measuring device used is VAC-FlowGuard-6280.

- The units used in this dynamic monitor system, model no. VAC-CPS6020/40 is Pascal.

- This isolation room pressure monitoring system has RS485 Modbus for internal communication.

- External communication is via RS485 Modbus RTU.

- The dimension of this dynamic monitor system, model no. VAC-CPS6020/40 is 150 x 100 x 5 (45 Mounting box) mm.

- This CSSD room monitoring system features an LCD with a 65 × 49 mm display. The LCD is a touchscreen.

- The control panel of this cleanroom pressure monitor system, model no. VAC-CPS6020/40 has a standard white colour. It can be customized as per request.

- The dimension of the attached box is 114 x 90 x 40 mm.

- The measurement of this cleanroom pressure monitor system, model no. VAC-CPS6020/40 is 150 x 100 x 40 mm on the wall box.

- The power supply for both models is 24 V DC @ 54 mA.

- Accuracy and annual drift usually depend on the attached sensor.

- Optionally, an output relay is available with 24 VAC/DC at 1A max current.

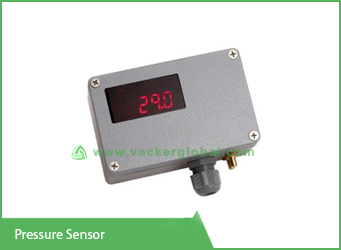

Features of Pressure Transmitter, model no. VAC-FlowGuard-6280 for room pressure sensor

This pressure transmitter is ideal to use for applications such as room pressure, static pressure, anterooms, laboratories, hospitals, IVF clinics, clean rooms, isolation room, airlock, Variable Air Volume boxes, industry, and server rooms.- This room pressure sensor system has a field configura

ble functionality such as signal output (mA or Volt) and signal volt output (0-10, 0-5, 2-10).

ble functionality such as signal output (mA or Volt) and signal volt output (0-10, 0-5, 2-10). - It features an LED monitor for configuration.

- This cleanroom pressure transmitter can be quickly mounted and programmed.

- A version with an optional alarm relay is available.

- The sensor of this pressure transmitter can be connected with the PSIDAC dynamic Central Panel System. All configurations and variables can be achieved from a BMS / SCADA via Modbus.

- This cleanroom pressure transmitter is a precise and flexible device.

- Optionally, a visible display is available.

- Auto calibration is optional for demanding applications.

Specifications of Differential Pressure monitoring sensor transmitter, model no. VAC-FlowGuard-6280 for CSSD rooms, Cleanrooms

- The detection ranges of this isolation room pressure transmitter, model no. VAC-FlowGuard-6280 are 0-500 Pa, ± 250 Pa, ± 500 Pa, ± 1250 Pa, and 0-2500 Pa. Additional ranges are offered

upon request.

upon request. - It has an optional relay with 24 VAC/DC at 1A max current.

- The output of this pressure transmitter, model no. VAC-FlowGuard-6280 are 0-5, 1-5, 0-10, 1-10, 2-10 V or 4-20mA, 0-20 mA.

- You can operate this differential pressure monitoring transmitter from a temperature range of -10 to 50 °C (-14 to 122 °F). *

- The typical non-linearity is ± 0.3 Pascal at +0.1% of reading.

- This differential room pressure monitor normally comes with a stability of ± 0.2 %. (1 year).

- The frequency response of this pressure transmitter, model no. VAC-FlowGuard-6280 is between 0.1 to 20seconds.

- The output range depends on the unit.

- The resolution of this pressure transmitter, model no. VAC-FlowGuard-6280 is 10-bit digital output.

- The power supply of this negative pressure monitor is 18-24 V AC/DC, 50 mA.

- It is suitable to operate in humidity range between 0 to 95 % RH (non-condensing).

- The dimensions of this pressure transmitter, model no. VAC-FlowGuard-6280 are 125 x 90 x 60 mm.

- The weight of this differential pressure transmitter, model no. VAC-FlowGuard-6280 is 530 g.

- The hose connectors ø is 5/ 6/ ¼” mm specified at order.

What is a Differential Room Pressure Sensor?

Negative Room Pressure Sensor

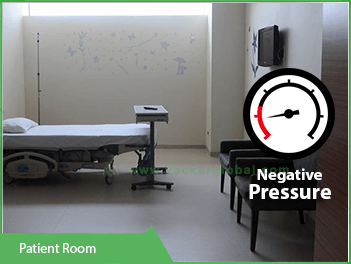

While mentioning about negative pressure, it is generally lower pressure than atmospheric pressure. Also, it can be lower pressure compared to an adjacent room. In all these cases, it is basically the difference in pressure. As an example, if you have a warehouse with huge exhaust fans it is removing air from the warehouse. If you do not have proper air intake systems the pressure inside the warehouse will become negative. Hence, you should have air intake systems which bring fresh air at the same rate as removal of air. And, both the systems should work simultaneously. If the exhaust fan is not working, the air intake system also should stop simultaneously. Otherwise, the higher intake will generate a positive pressure inside the warehouse. A negative pressure sensor constantly checks whether the pressure is becoming negative.Positive Room Pressure Sensor

Positive pressure and negative pressure sensors are two elements of the same differential pressure monitoring system. In the above example, you need to ensure that the pressure does not become positive nor negative. In this case, you do not need a separate positive pressure sensor and another negative pressure sensor. You will require one room pressure monitoring system having two air pipes. One pipe will be positioned inside the warehouse and the second one outside the warehouse. We can program the same to ensure that the inside pressure is always the same as outside pressure.

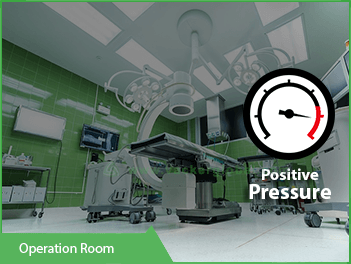

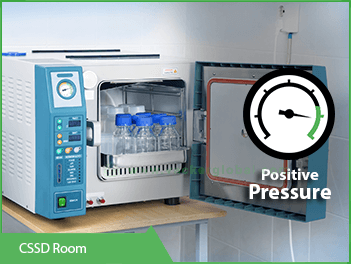

Room pressure monitoring for hospitals

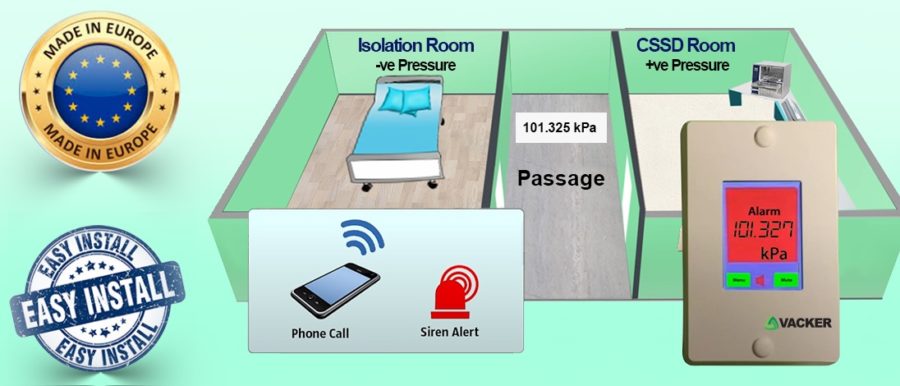

In hospitals, there are a lot of critical areas such as operation theatres, isolation wards, critical care units, laboratories etc. We need to maintain a pressure difference for such rooms. This requires continuous room pressure monitoring systems. Major use in hospitals is for isolation wards, which maintain a slightly lower pressure than the surrounding rooms. As this room has a lower pressure, the contaminated room will not go out of the room. This will mainly prevent the spread of airborne diseases. Air will flow from the outside into this room, but not reverse. As this is a very critical requirement, our reliable negative room pressure monitoring can be installed for this purpose. We will install one air pipe in the isolated room and another one outside this room. This monitors that the isolated room always has negative pressure. Similarly, there are positive pressure rooms in hospitals which will provide a clean environment. These rooms are for sterile equipment, for patients with low body resistance etc. In this case, we use the term positive room pressure monitoring system. Also, all the Central sterile supply department (CSSD) areas in hospitals will require differential pressure monitoring systems.Isolation room sensor

The isolation rooms are at negative pressure so that air does not go out of the room spreading diseases to other areas of a hospital. For such applications, a hospital requires differential pressure sensors. In this case, we call it simply as isolation room sensor. But the device is exactly the same without any technical difference. The device will continuously monitor the room inside the isolation room and the pressure outside the room. If the pressure inside the isolation room is lesser than that outside, it is safe. Otherwise, the sensors will make alerts such as audible alarm, telephone calls etc. using auxiliary systems.Features of our Room pressure monitoring system model 6000

We supply our model 6000 room pressure monitoring system for all commercial applications. You can use the same system for negative pressure monitoring and positive pressure monitoring. You can always adjust the desired pressure level in the configuration. This way you don’t have to worry about the pressure reading before installation. After the installation, you can configure as required by you. Major features of the system are explained below:

We supply our model 6000 room pressure monitoring system for all commercial applications. You can use the same system for negative pressure monitoring and positive pressure monitoring. You can always adjust the desired pressure level in the configuration. This way you don’t have to worry about the pressure reading before installation. After the installation, you can configure as required by you. Major features of the system are explained below:

- One device can monitor up to 4 rooms simultaneously. Also, you can expand the same system using additional subunits.

- It uses sealed membrane capacitive measurement technology for better accuracy. This will prevent any air particles or dust from escaping from one room to another.

- The system can generate alerts if the programmed pressure is not maintained.

- If you require monitoring on your computer through your local area network, the same is possible. Also, the system can work as a standalone unit without connecting to a centralized network.

- We can connect an external alarm to a nursing station or another remote room. Also, the customer can connect a SIM card based phone call and SMS alert system. In this case, it will generate phone calls to 4 operators in case of an alert.

- The system will display green if everything is OK. In case of an alert, it will display red on the screen.

- The customer can mount on the surface of the wall. Alternatively, the customer can flush mount the same after making a cavity.

- The display screen is a touch screen having a dimension of 65 x 50mm.

- We can connect many devices together to a network th

rough a Modbus protocol.

rough a Modbus protocol. - The measurement unit is Pascal.

- The room pressure monitoring system has an accuracy of 0.5 Pa.

- The dimension of the unit is 150x100x5 mm.

- We can connect one analogue output of the monitoring system to a VAV system for controlling the airflow.

Negative pressure room

Negative pressure room is generally used in many hospitals and medical centres to reduce the chances of contamination from one room to another. In a negative pressure room, the air pressure in the room is always maintained lower than the atmospheric pressure or from the adjacent environment. Negative pressure in the room is maintained through a ventilation system. The ventilation system in the room is designed in such a way that air from the ambient environment can enter the room but is prevented to flow out as the contaminated air from the room can affect other rooms. The ventilation system in the room continuously forces out the internal air from the room to a certain destination to create negative pressure in the room. These types of rooms are generally used for the patients that are suffering from airborne communicable diseases. Negative pressure room is very important for hospitals to protect the working staff and other patients in the hospital from getting the disease spread out. Many people visit hospitals every day, negative pressure rooms helps to stop spreading of airborne diseases from spreading out to those people from the patients in the hospital. These negative pressure rooms are more important for people having a weaker immune system such as babies and old people. People suffering from diseases like Covid-19, tuberculosis, respiratory illnesses etc. are kept in a negative pressure room. These diseases can easily be transferred through the air. Negative pressure rooms stop the spreading out of harmful germs such as yeasts, bacteria, viruses, fungi etc. other parts of the room. The negative pressuring is generally used in isolation rooms. This helps hospitals or medical centres to be a safer place for patients and staffs. Some of the rooms that need to be negatively pressurized are emergency waiting room, dark rooms, autopsy rooms, restrooms, isolation rooms for patients suffering from airborne disease, microbiology laboratories, pathology, sterilizing laboratories, decontamination room and many more. Hence, this shows that there is a huge importance of negative pressure rooms in health care and medical centres. In fact, without negative pressure rooms, hospitals will be a dangerous place for the people as instead of getting well from the disease from the hospital it is more likely that the patient will get infected by more diseases. Hence the code for health care centres strictly wants hospitals and health centres to have negative pressure rooms.

Negative pressure room is very important for hospitals to protect the working staff and other patients in the hospital from getting the disease spread out. Many people visit hospitals every day, negative pressure rooms helps to stop spreading of airborne diseases from spreading out to those people from the patients in the hospital. These negative pressure rooms are more important for people having a weaker immune system such as babies and old people. People suffering from diseases like Covid-19, tuberculosis, respiratory illnesses etc. are kept in a negative pressure room. These diseases can easily be transferred through the air. Negative pressure rooms stop the spreading out of harmful germs such as yeasts, bacteria, viruses, fungi etc. other parts of the room. The negative pressuring is generally used in isolation rooms. This helps hospitals or medical centres to be a safer place for patients and staffs. Some of the rooms that need to be negatively pressurized are emergency waiting room, dark rooms, autopsy rooms, restrooms, isolation rooms for patients suffering from airborne disease, microbiology laboratories, pathology, sterilizing laboratories, decontamination room and many more. Hence, this shows that there is a huge importance of negative pressure rooms in health care and medical centres. In fact, without negative pressure rooms, hospitals will be a dangerous place for the people as instead of getting well from the disease from the hospital it is more likely that the patient will get infected by more diseases. Hence the code for health care centres strictly wants hospitals and health centres to have negative pressure rooms.

Positive pressure room

Positive pressure rooms are the adjacent opposite of negative pressure rooms. In a negative pressure room, the room has lower air pressure than its ambient environment but in a positive pressure room, the room has higher air pressure than its ambient environment. In a negative pressure room, the ventilation system is designed in such a way that the air from the environment can enter the room but the air from the room cannot escape while in positive pressure room the air from the room can escape but air from the environment cannot enter the room. The ventilation of the positive pressure room consists of fans or filters. These fans or filters help to create high air pressure by blowing air into the room. It creates positive air pressure inside the room and prevents the air from the ambient environment from entering the room. The room must be properly sealed to maintain the positive air pressure in the room. Generally, a positive pressure room is used to prevent contamination from the ambient environment to enter the room. These positive air pressure rooms are used in cleanrooms. They are also used in other sensitive areas such as oil platform. These positive pressure rooms are also widely used in operating theatres. This protects the patient to be protected from infection from an external agent during the operation. Hospitals also use positive pressure room to keep patients with a weak immune system. These patients can get easily affected by external contamination or pathogens such as bacteria, viruses, fungi etc. Positive pressure rooms help to keep the environment safer for such type of patients. Another use of positive air pressure rooms in hospitals can be seen in vitro fertilization room. One of the most common uses of positive air pressure is in the cleanrooms. To maintain a cleanroom the room must be sealed from external air, dirt, dust and other microorganisms. Creating positive air pressure and turning the clean rooms into positive pressure rooms helps to prevent the external agent. Examples of cleanrooms having positive air pressure are pharmaceutical production clean rooms, medical production clean rooms, medical research clean rooms, pharmaceutical research room, chemical laboratory clean rooms, etc. These positive air pressure rooms are also used in cleanrooms that are related to aerospace, optics and electronics. The positive air pressure in such clean rooms helps the user to comply with the required standards of the cleanrooms.

Positive pressure rooms are the adjacent opposite of negative pressure rooms. In a negative pressure room, the room has lower air pressure than its ambient environment but in a positive pressure room, the room has higher air pressure than its ambient environment. In a negative pressure room, the ventilation system is designed in such a way that the air from the environment can enter the room but the air from the room cannot escape while in positive pressure room the air from the room can escape but air from the environment cannot enter the room. The ventilation of the positive pressure room consists of fans or filters. These fans or filters help to create high air pressure by blowing air into the room. It creates positive air pressure inside the room and prevents the air from the ambient environment from entering the room. The room must be properly sealed to maintain the positive air pressure in the room. Generally, a positive pressure room is used to prevent contamination from the ambient environment to enter the room. These positive air pressure rooms are used in cleanrooms. They are also used in other sensitive areas such as oil platform. These positive pressure rooms are also widely used in operating theatres. This protects the patient to be protected from infection from an external agent during the operation. Hospitals also use positive pressure room to keep patients with a weak immune system. These patients can get easily affected by external contamination or pathogens such as bacteria, viruses, fungi etc. Positive pressure rooms help to keep the environment safer for such type of patients. Another use of positive air pressure rooms in hospitals can be seen in vitro fertilization room. One of the most common uses of positive air pressure is in the cleanrooms. To maintain a cleanroom the room must be sealed from external air, dirt, dust and other microorganisms. Creating positive air pressure and turning the clean rooms into positive pressure rooms helps to prevent the external agent. Examples of cleanrooms having positive air pressure are pharmaceutical production clean rooms, medical production clean rooms, medical research clean rooms, pharmaceutical research room, chemical laboratory clean rooms, etc. These positive air pressure rooms are also used in cleanrooms that are related to aerospace, optics and electronics. The positive air pressure in such clean rooms helps the user to comply with the required standards of the cleanrooms.

Differential pressure sensors for HVAC systems

An HVAC system, when combined with a proficient Differential pressure, can lead to a thriving combination. HVAC systems aren’t that good to cater the maintenance as well as the security needs of today’s buildings. The growing demand aims for new solutions; the prime goal is to keep occupants of the buildings or offices safe. A great deal of security can be obtained by leveraging the potential of the HVAC- Differential pressure sensor combo. An array of applications come handy for the purpose of installing an HVAC- Differential pressure sensor system, you can utilize them for keeping a check on the indoor air’s quality level. Keep your loved ones safe by letting them breathe fine air, monitor air quality with the help of Differential pressure sensors for HVAC systems now. It is obvious that buildings must have a way for air to initiate an airflow. Measure the desired data with added ease by the aid of the pressure sensors combined with your HVAC system. When it comes to quality, a differential pressure sensor for HVAC system never jeopardizes the user. When it comes to any sorts of quandary or sudden change in air pressure, the pressure sensor informs the user at ease. Measuring the air pressure amongst your room is what differential pressure sensors for HVAC systems are best at. What comes a great fact is that you can utilize the benefits of the technology and can deploy room pressure sensors for hospitals as well. Get instant updates when the filters require a clean-up. Stairwell pressurization is dealt with much per

An HVAC system, when combined with a proficient Differential pressure, can lead to a thriving combination. HVAC systems aren’t that good to cater the maintenance as well as the security needs of today’s buildings. The growing demand aims for new solutions; the prime goal is to keep occupants of the buildings or offices safe. A great deal of security can be obtained by leveraging the potential of the HVAC- Differential pressure sensor combo. An array of applications come handy for the purpose of installing an HVAC- Differential pressure sensor system, you can utilize them for keeping a check on the indoor air’s quality level. Keep your loved ones safe by letting them breathe fine air, monitor air quality with the help of Differential pressure sensors for HVAC systems now. It is obvious that buildings must have a way for air to initiate an airflow. Measure the desired data with added ease by the aid of the pressure sensors combined with your HVAC system. When it comes to quality, a differential pressure sensor for HVAC system never jeopardizes the user. When it comes to any sorts of quandary or sudden change in air pressure, the pressure sensor informs the user at ease. Measuring the air pressure amongst your room is what differential pressure sensors for HVAC systems are best at. What comes a great fact is that you can utilize the benefits of the technology and can deploy room pressure sensors for hospitals as well. Get instant updates when the filters require a clean-up. Stairwell pressurization is dealt with much per fection by Differential pressure for HVAC systems.

fection by Differential pressure for HVAC systems.

Specifications of the wall-mounted room pressure monitor

6280_B_2500 + 2500 6280_B_1250 0-1250 6280_500 0-500Pa 6280_B_250 +250Pa 6280_B_500 +500Pa Total error* Typical +0.5 Pa l (500/B250 pa sensor) Stability Typ.>1 Pa. (1 year) Time Constant 0.1 - 20 seconds Output 0-5,1-5,0-10,1-10,2-10 V 4-20mA, 0-20 mA Output Range 5, 10, 25, 50, 75,100,125,250,300,500 ±5, 10, 25, 50, 75,100,125,250,300,500 Resolution 10 bit digital output Supply 15-24 V AC/DC, 50 mA Operating temp -10C - +60C Storage Temp: -40C - +50C Enclosure Aluminum IP rating IP 65 with mounted seal Media Air /dry gases Dimension 125x90x60 mm Weight 530 g Pressure connector Dy 5 mm/Opt 6.2 mm _____________________________________________________________All models are available with Inch Specification. Details are subject to change without notice. *Other ranges and options available, all sensors have a number of sub-settings depending on the main range. User can specify new ranges when ordering. (* Temperature effects 10-40 C less than +-2% of span)

Product Description of Room pressure Sensor

- Brief Title of the device: Negative room pressure sensors and Differential pressure monitoring systems.

- Brief Description of the device: This room pressure monitoring sensor system is for monitoring pressure difference in rooms. Typical applications are for CSSD rooms, isolation wards, operations theatres, clean rooms, laboratories, research centres etc. It can monitor differential pressure, positive pressure and negative pressure. You can operate it on isolated mode or connected to a local computer network. You can connect it to an alarm system, phone call & SMS alert system. This set is suitable for 2 rooms.

- Model number: VAC-CPS-6020/40

- Brand: VackerGlobal

- Seller: VackerGlobal

- SKU Number:1008000049

- Price (USD): 1635.00

- Price Validity: 31 December 2021

FAQ on Differential, Positive and Negative room pressure sensors and monitoring system

- What is a negative pressure room & its purpose?: The purpose of a negative pressure room is that the air from this room should not go out to other rooms. Consider a negative pressure isolation room with a patient with a respiratory illness such as Covid-19. The air within this room may contain the Covid-19 virus. This air should not go to other areas of the hospital. In order to achieve this, the pressure inside this negative pressure room should always be lower than the surrounding rooms. eg. Assume that the normal pressure in the corridor is 101,325 Pa (1,013.25 hPa, 1,013.25 mbar, 760 mm Hg, 29.9212 inches Hg, or 14.696 psi). A room with a pressure of 101,320 Pa (1,013.20 mbar) is a negative pressure room.

- What is a positive pressure room & its purpose?: The purpose of a positive pressure room is that outside air should not come to this room from the corridor or other rooms. The room pressure will be slightly higher than the air pressure in the corridor. Consider an operation theatre, which always has positive pressure. The purpose is that air with any airborne particles or pathogens should not enter this room. This will compromise the safety of the patient being operated. eg. Assume that the normal pressure in the corridor is 101,325 Pa (1,013.25 hPa, 1,013.25 mbar, 760 mm Hg, 29.9212 inches Hg, or 14.696 psi). A room with a pressure of 101,330 Pa (1,013.30 mbar) is a positive pressure room.

- What is the pressure to be maintained in a negative pressure room in mbar, kPa or psi?: International bodies specify that a negative pressure room should maintain a negative pressure between 0.01 to 0.03 inches of Water Column (WC). This corresponds to 2.4884 Pascal (Pa) and 7.4652 Pascal (Pa) respectively. Assume that the air pressure in the corridor is 101,325 Pa. This means that the negative isolation room should have pressure between 101,322.51 Pa (1,013.225 mbar) and 101,317.53 Pa (1,013.175 mbar).

- What is the pressure to be maintained in a positive pressure room in mbar, kPa or psi?: International bodies specify that a positive pressure room should maintain a positive pressure of 0.01 to 0.03 inches of Water Column (WC). This corresponds to 2.4884 Pascal (Pa) and 7.4652 Pascal (Pa) respectively. As per the previous example, assume that the air pressure in the corridor is 101,325 Pa. This means that the negative isolation room should have a pressure between 101,327.49 Pa (1,013.274 mbar) and 101,332.47 Pa (1,013.324 mbar)

- How to design an airborne infection isolation room (AIIR)? : An AIIR is a negative pressure room. This means that the air pressure within the room is lower than the atmospheric pressure. The pressure should be lower by pressure between 2.4884 Pascal (Pa) to 7.4652 Pascal (Pa). The only air opening to the room from the outside should be through the gap under the door. The air going out of the room through the negative pressure generator should be treated with a HEPA filter. The room should have a differential pressure monitoring system. In case the pressure difference is not proper, it should generate an alert. The patient should not be able to operate the pressure control system of the room.

- What is a differential pressure monitor or negative room pressure monitor for isolation rooms?: Maintaining negative pressure in an airborne infection isolation room is essential. Hence the hospital has to monitor this pressure at all times. You can achieve this using a differential pressure monitor. This is same as a negative room pressure monitor or positive room pressure monitor. A single device serves all these purposes. It constantly monitors the room pressure and outside pressure. In case the pressure difference is not proper, it gives an alert. The alert can be a local siren, phone call, SMS, alert at nursing station etc.

- How to convert an existing room into a negative pressure isolation room? In order to convert an existing room into negative pressure, the pressure inside the room has to be slightly lower than atmospheric pressure. In order to achieve this, we have to remove air from this room continuously. This air should be thrown out of the room into the environment after cleaning. Also, the air has to be purified before being thrown out of the building. We supply negative pressure generators combined with HEPA filters and UV lights to achieve this. Please contact us for more details.

- How to convert an existing room into a positive pressure room? Converting an existing room into a positive pressure room is easier than converting into a negative pressure room. If you have an existing HVAC system, you can increase the airflow into the existing room. This will make the pressure inside the room slightly higher at all times. The airflow has to be at higher levels at all times and not just during the functioning of the airconditioning.

- How to select a room pressure monitoring system? You have to identify your requirements: (a) Do you want a system with or without connection to a computer network or Building Management System (BMS) (b) The type of alarms you require viz. phone, SMS, local alarm etc. (c) The number of adjacent rooms that needs monitoring. Select a single system which can monitor the maximum number of rooms (d) Connection facilities to a nearby nursing station (e) Local display unit to indicate the current status (f) Ease of installation in an existing building. (g) The same system is useful for both positive and negative pressure rooms. Hence this is not a major criterion.